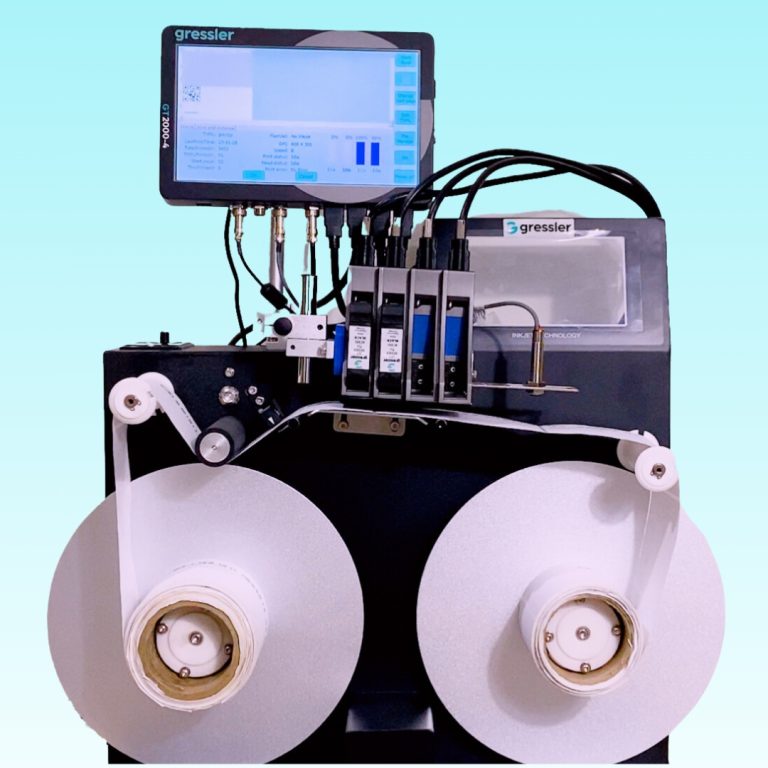

The Gressler Label Rewinder Coding Inkjet, part of the CMS TJR 1030 package series, offers an integrated solution combining a rewinder with Gressler’s TIJ thermal inkjet printer, catering to industries requiring simultaneous label rewinding and printing capabilities.

Operating at high speeds, the Gressler rewinder coding inkjet ensures uninterrupted and stable performance, making it particularly suitable for industries with demanding production environments, thereby enhancing productivity and efficiency. Synchronous printing during the rewinding process ensures clear and identifiable content on labels, essential for maintaining product integrity and complying with industry standards.

The integrated design promotes compact and tidy label recycling, streamlining the handling of recycled labels and contributing to a more organized production setup.

Rewinder module features:

Input voltage/product power: 220V, 50Hz/30W

Speed range: 0-60m/min

Core size: 38mm/76mm

Printing module feature:

Print Resolution: 150-600 DPI 150-600 DPI

Power requirements: 100-240 VAC, 50-60Hz, DC24V 2.5A

The CMS TJR 1030 operates at high speeds, ensuring uninterrupted and stable performance. This feature is particularly beneficial for industries with demanding production environments, contributing to enhanced productivity and efficiency.

Synchronous printing during the rewinding process ensures clear and identifiable content on labels. This capability is essential for maintaining product integrity and complying with industry standards, ensuring accurate product identification throughout the supply chain.

The integrated design promotes compact and tidy label recycling, streamlining the handling of recycled labels and contributing to a more organized production setup. This feature helps optimize space utilization and facilitates a smoother workflow in the production environment.

Equipped with Gressler's self-developed TIJ thermal inkjet printer, the rewinder features real-time printing cost calculation capabilities. This functionality provides businesses with accurate insights into printing expenses, enabling better cost management and decision-making.

Gressler's TIJ thermal inkjet printer is renowned for its powerful functions and stable structure. The combination of these attributes ensures reliable and consistent printing results, enhancing the overall effectiveness of the rewinding process and contributing to the efficiency of the production line.