Gressler offers Laser Marking technology in several types, each designed for specific materials and applications:

CO2 laser marking utilizes carbon dioxide gas to generate a laser beam. This technology is well-suited for marking non-metal materials such as paper, wood, rubber, and plastic. It’s a versatile solution for applications that require precise and high-quality markings on a variety of surfaces.

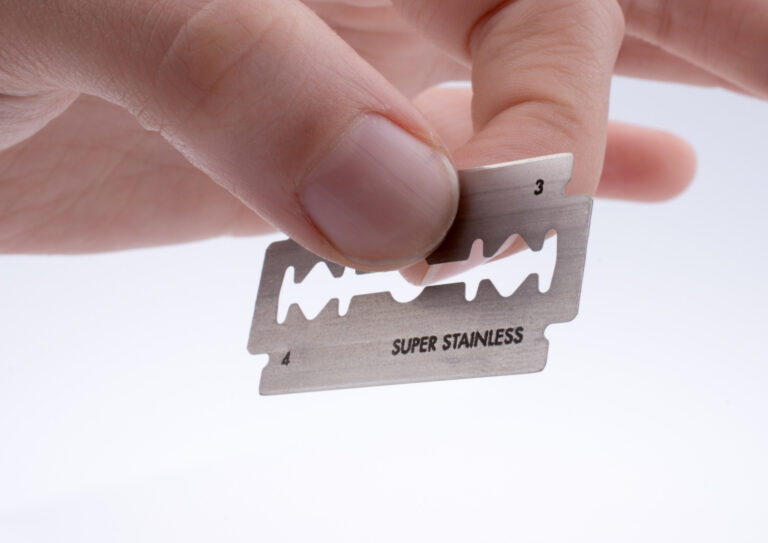

Fiber laser marking uses reinforced optical fibers to produce a laser beam. This technology is ideal for marking metal materials and some non-metals like dark-colored plastics. It delivers high precision and is particularly effective for industrial applications where speed and durability are essential.

UV laser marking utilizes ultraviolet light to create permanent markings on materials. This technology is perfect for materials that are sensitive to heat or require extremely fine and high-contrast markings. It is particularly valuable in industries such as cosmetics, pharmaceuticals, and high-end electronics, where precision and aesthetic quality are critical.

CO2 laser coding provides high-quality marking on materials such as paper, cardboard, plastic, and wood. The CO2 laser technology produces clear and precise markings, making it ideal for packaging, labeling, and industrial engraving.

Fiber laser coding provides fast and precise marking on metals and plastics. With advanced fiber laser technology, this machine offers high durability and efficiency, making it ideal for industrial applications such as engraving, serialization, and barcode creation.

UV laser coding delivers high-precision markings with minimal heat on sensitive materials like glass, plastic, and ceramics. The short wavelength allows for fine and detailed markings without damaging the material, making it ideal for electronics, medical devices, and complex industrial applications.

Gressler Laser Marking enables the highest precision and detail in marking applications. Designed for sharp accuracy, this fiber laser system allows for the creation of intricate details, fine lettering, and complex patterns with ease, making it the ideal choice for industries where precision is essential.

Gressler's laser marking systems are designed with industrial-grade components, ensuring that the markings are permanent and resistant to abrasion, heat, and chemicals. This makes them ideal for products exposed to harsh conditions. The durable nature of the marks ensures long-lasting traceability and product integrity, even in challenging environments.

This system is particularly well-suited for markets that demand ultra-fine processing, such as cosmetics and pharmaceuticals. The precision and quality of Gressler’s UV laser marking meet the high standards required for luxury goods and sensitive products, enabling manufacturers to add value through superior aesthetics and packaging integrity.

The compact and solid-state design of Gressler's Laser Fiber system requires minimal maintenance, reducing operational costs and production downtime. Combined with the long lifespan of its optical fiber components, this machine offers enhanced cost-effectiveness over time, ensuring reliable performance and a lower total cost of ownership for businesses.