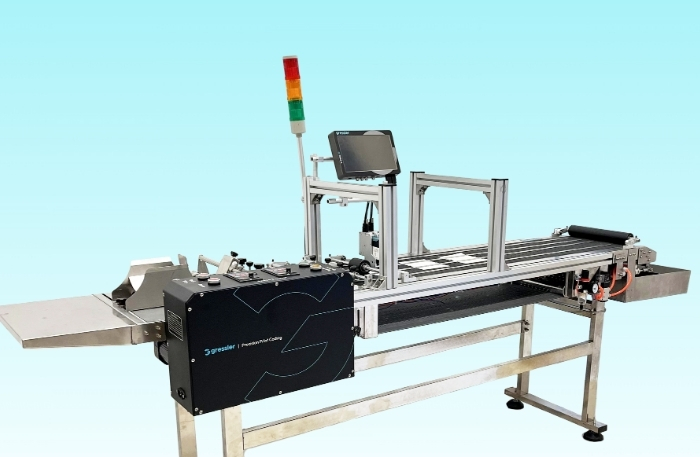

The Gressler GAP-90PX is a cutting-edge coding, code-reading, and paging system designed to meet the rigorous demands of modern production lines. Combining high-speed performance, advanced code detection, and versatile material compatibility, this system is engineered to enhance productivity, ensure accuracy, and maintain the highest quality standards.

Whether you’re working with bags, cartons, or paper cards, the GAP-90PX delivers unmatched efficiency and reliability, making it an indispensable tool for industries that require seamless integration of coding, inspection, and paging processes.

At the core of the GAP-90PX is its ability to deliver blazing-fast paging speeds of up to 90 meters per minute. This exceptional speed ensures that your production line operates at maximum efficiency, even during high-demand operations. Whether you’re handling large volumes or tight deadlines, the GAP-90PX keeps your workflow smooth and uninterrupted, significantly boosting productivity and reducing downtime.

Motor: 200W variable frequency motor

Power Supply: 220V/50Hz

Power: 200W

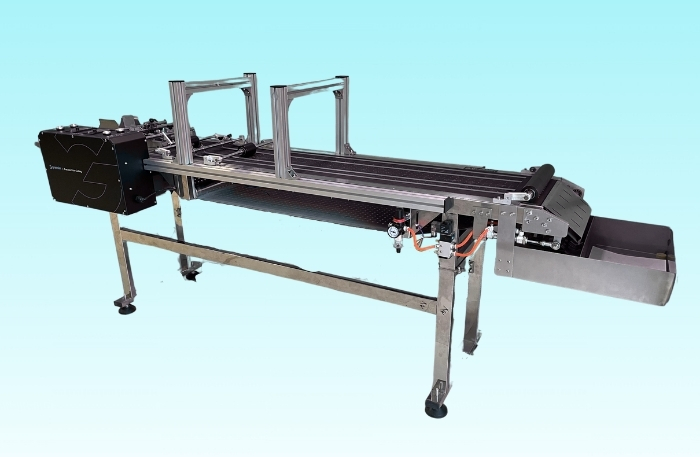

Conveyor Belt Size: 300mm width × 2170mm length, made from durable black PVC

Machine Dimensions: 1500 × 390 × 770mm (L × W × H)

Paging speed : 0-90m/min

Achieves paging speeds of up to 90 meters per minute, ensuring maximum productivity for high-demand operations.

Supports a wide range of materials, including bags, cartons, and paper cards, with adjustable paging methods (friction or baffle types) and accommodates product widths of 130–300mm and heights of 1.2–20mm.

Features a built-in visual inspection system with a code-reading speed of 75m/min and missing code detection speed of 110m/min, ensuring precise quality control and error-free operations.

Equipped with an optional rejection system to automatically remove products with missing or incorrect codes, maintaining seamless production flow and reducing waste.